For Practical Use

Scope of Application

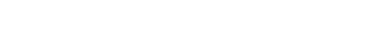

The equipment used for the AK2 cutter method is a Ø2,000 mm type all-rotation

excavator. Suitable for the removal of piles with a diameter of Ø1,500 mm. Since the

horizontal cutting blade is attached inside the Ø2,000 mm casing, the excavation hole

is protected by the casing from excavation to backfilling, so it may prevent the collapse

or loosening of the ground from occurring. The removal work that does not affect

surrounding structures is possible. Further, with this configuration, the removal length

of the existing pile can be set arbitrarily, so that only the necessary part can be

removed.

In addition, since the excavated hole is protected throughout the hole by the casing,

for backfilling after removal, it is possible to choose methods of filling the hole with

excavated soil or cement mortar.

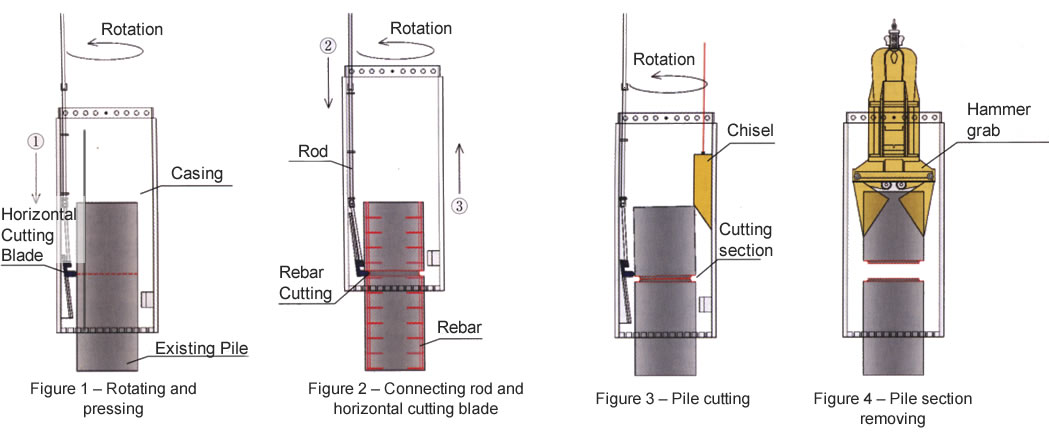

The purpose of AK2 horizontal cutting blade is to cut main reinforced steel bars. After

the cutting is completed, only the concrete remains inside with poor cutting resistance,

so it can be easily cut by inserting a chisel and rotating the casing. This method

reduces the time required for cutting.

APPLYING AK2 METHOD TO PRACTICE

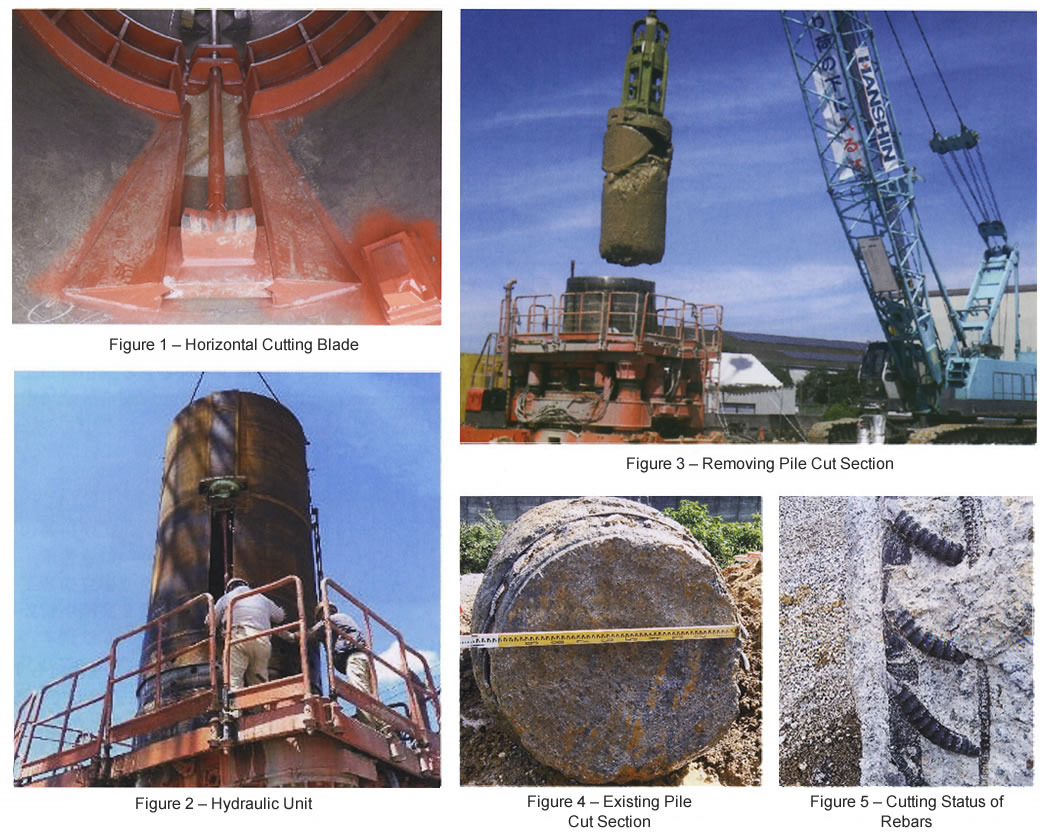

Visualize Control Panel

By attaching a stroke sensor to the hydraulic cylinder, a numerical value is displayed

on the control panel monitor, from which we can know the displacement of the blade

in the ground. Control the blade by the radio system. Figure 6 shows the operating

status of the monitor on the control panel.

Simple Operation

Operation on the control panel is actually only 2 buttons: shrinking and stretching the

cylinder, so manipulating the blade is relatively simple. Later, as we continue to

develop, we will aim at semi-automation by taking in the data of the rotational torque

from the all-rotation excavator. (Figure 7 - Control panel)

Improve The Durability Of Cutting Blades

If the durability of the horizontal cutting blade is further improved, the cutting speed

can be expected to increase. Currently, we are developing the shape and hardness of

the cutting blade. Figure 8, showing the state and speed of rebars cutting when

changing the shape and hardness of cutting blades.

AK cutter

For pile diameters of Ø1,000mm and Ø1,200mm, there is a fixed horizontal cutting

blade without a hydraulic unit. Horizontal cutting AK cutter can be easily attached to

the equipment of the conventional all-casing method as shown in Figure 9.

Construction Example

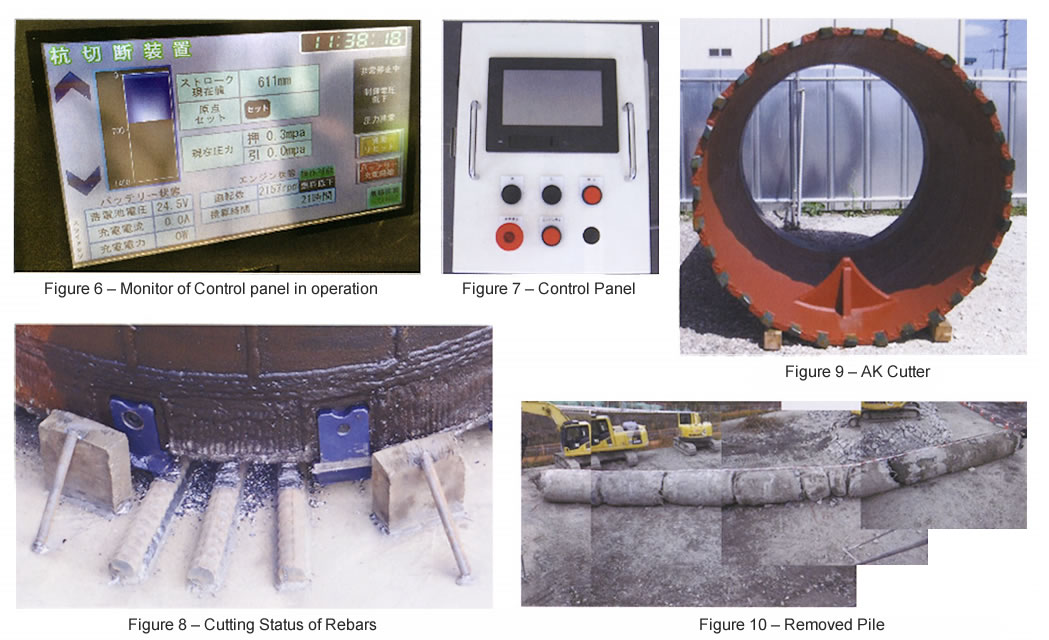

Removing existing cast-in-place pile for a high-standard dike maintenance

With the improvement of a high-standard dike in the city’s rivers renovation project,

existing condominiums were demolished, accompanied by the removal of the

foundation piles. Also, the protection dike is close to an operating railway line, as well

as a factory in operation, so an environmentally friendly construction method was

necessary.

The cast-in-place pile (Ø1,600mm x 23.0m) was removed by the AK2 cutter method.

Figure 10 - the entire pile were removed.

IN CONCLUSION

The idea of a horizontal cutting method for existing cast-in-place piles was developed around

2005, and the developers obtained a patent in 2008.

After that, it was put into practical use, and our AC group made further improvements.

In October 2014, the AC Group which includes companies and manufacturers with bases in

major cities nationwide such as Hanshin Kensetsu Co.,Ltd., Shinmei Gikou Co.,Ltd., Marui

Jyuki Kensetsu Co.,Ltd., Mitsuwa Kougyo Co.,Ltd., Sougou Kiso Co.,Ltd., Sanyo-Doboku

Co.,Ltd., Miyazaki Kiso Kensetsu Co.,Ltd., Asahi Giken Co., Ltd., Eiko Co., Ltd., and 2 other

companies, have been established, aiming to develop the construction industry and contribute

to society.

In the future, the AC Group will continue to make technical improvements to the AK2 cutter

method, in order to create a safe and environmentally friendly construction method.

[Patent No. 4106374] << Patent Related To AK2 Cutter Construction Method >>

Name of Invention: Demolishing Method for Existing Piles

[Patent No. 3683229] << Patent Related To AK Cutter Construction Method >>

Name of Invention: Existing Pile Removal Method And Equipment